ELIMINATE METAL BURRS WITH HIGH-PRECISION

THERMAL DEBURRING

WHAT IS THERMAL DEBURRING?

Thermal deburring (or thermal energy method deburring, TEM) is a process used to remove burrs, flash, or other unwanted material from metal or plastic parts by exposing them to a high-temperature combustion process. In this method, the parts are placed in a sealed chamber where a mixture of fuel gas and oxygen is ignited. The resulting rapid combustion generates intense heat that burns away small protrusions without affecting the base material. This technique is particularly useful for hard-to-reach areas, making it ideal for complex geometries or precision components.

-

Efficient burr removal: Reaches and eliminates burrs in internal cavities, threads, and intricate geometries.

Consistent results: Produces uniform and repeatable finishes across batches.

Non-contact process: Reduces risk of part distortion or damage.

High speed: Completes deburring in seconds, minimizing production time.

Versatility: Works on a variety of materials, including metals and some plastics.

Improved quality: Prepares parts for further processing, such as coating or assembly.

High Cleaning Precision: Ideal for intricate or delicate parts with complex geometries.

Residue-Free Finish: Leaves no residue, ensuring spotless surfaces.

Time Efficiency: Cleans and dries parts quickly in one streamlined process.

Environmentally Controlled: Performed in a closed system to reduce solvent emissions and maintain safety.

Consistent Results: Reliable and repeatable cleaning quality.

Material Compatibility: Safe for a wide range of materials, including metals, plastics, and ceramics.

Solvent Reuse: Allows solvent recovery and reuse, lowering operational costs.

Reduced Labor: Minimizes manual handling and cleaning effort.

Compliance with Standards: Meets high industry cleanliness requirements for aerospace, medical, and electronics applications.

Effective for Heavy Contamination: Excels in removing stubborn contaminants like oils, waxes, and greases.

-

Industry Applications

Automotive: Deburring engine components, fuel injectors, and transmission parts.

Aerospace: Refining complex turbine blades, hydraulic components, and precision machined parts.

Medical Devices: Ensuring smooth, burr-free edges on surgical instruments and implants.

Manufacturing: Removing burrs from gears, valves, and other precision-machined parts.

Electronics: Cleaning connector pins and components with intricate shapes.

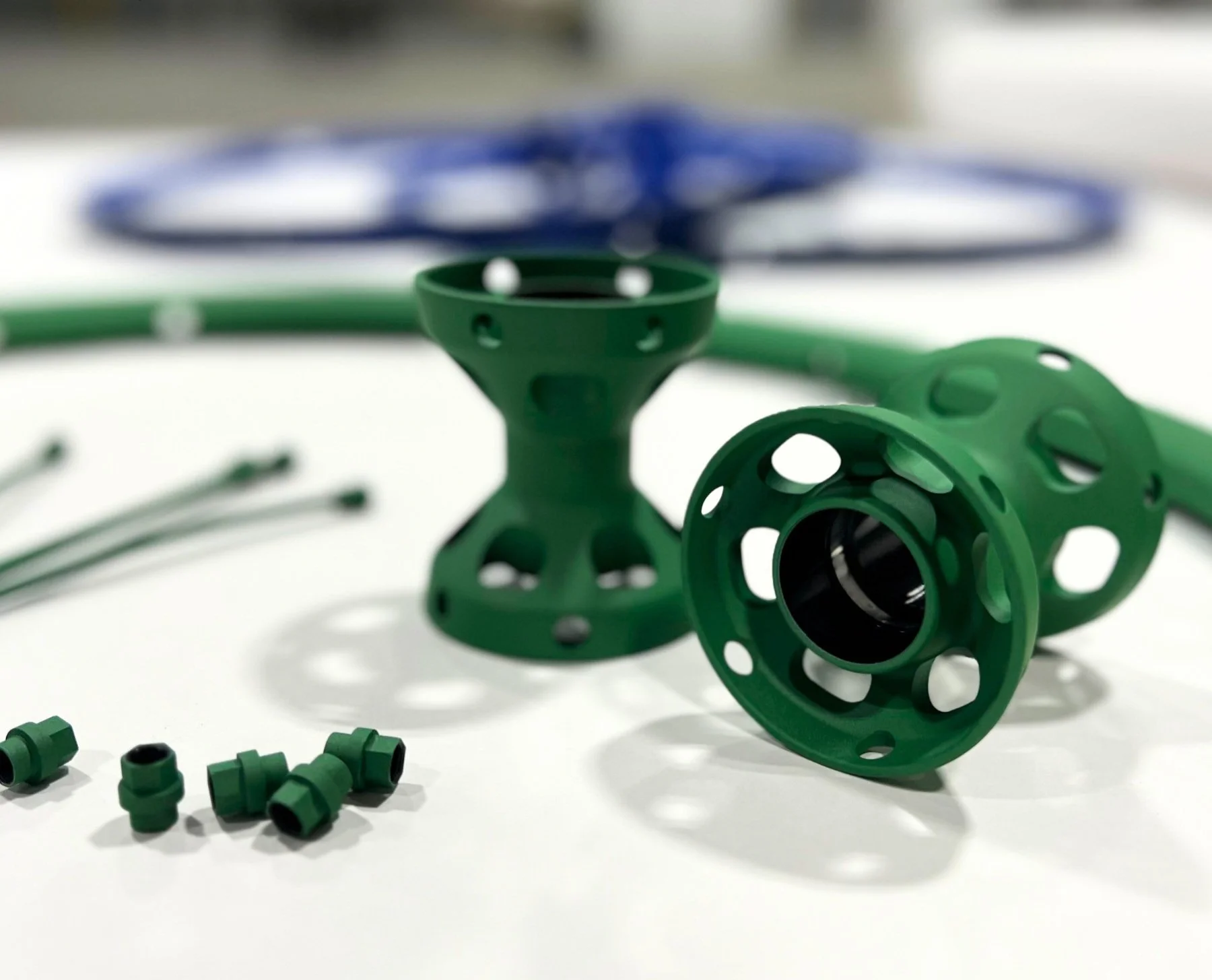

Common Parts

Engine and Transmission Components: Pistons, housings, and injector nozzles.

Hydraulic and Pneumatic Parts: Valves, fittings, and manifolds.

Precision Machined Parts: Gears, threads, and small holes or cavities.

Medical Instruments: Orthopedic implants and surgical tools.

Electronic Connectors: Pins and contacts requiring smooth edges.

Thermal deburring is an excellent choice for manufacturers looking to achieve superior quality and efficiency, especially when dealing with intricate parts and tight tolerances.