VAPOR DEGREASING

& CLEANING

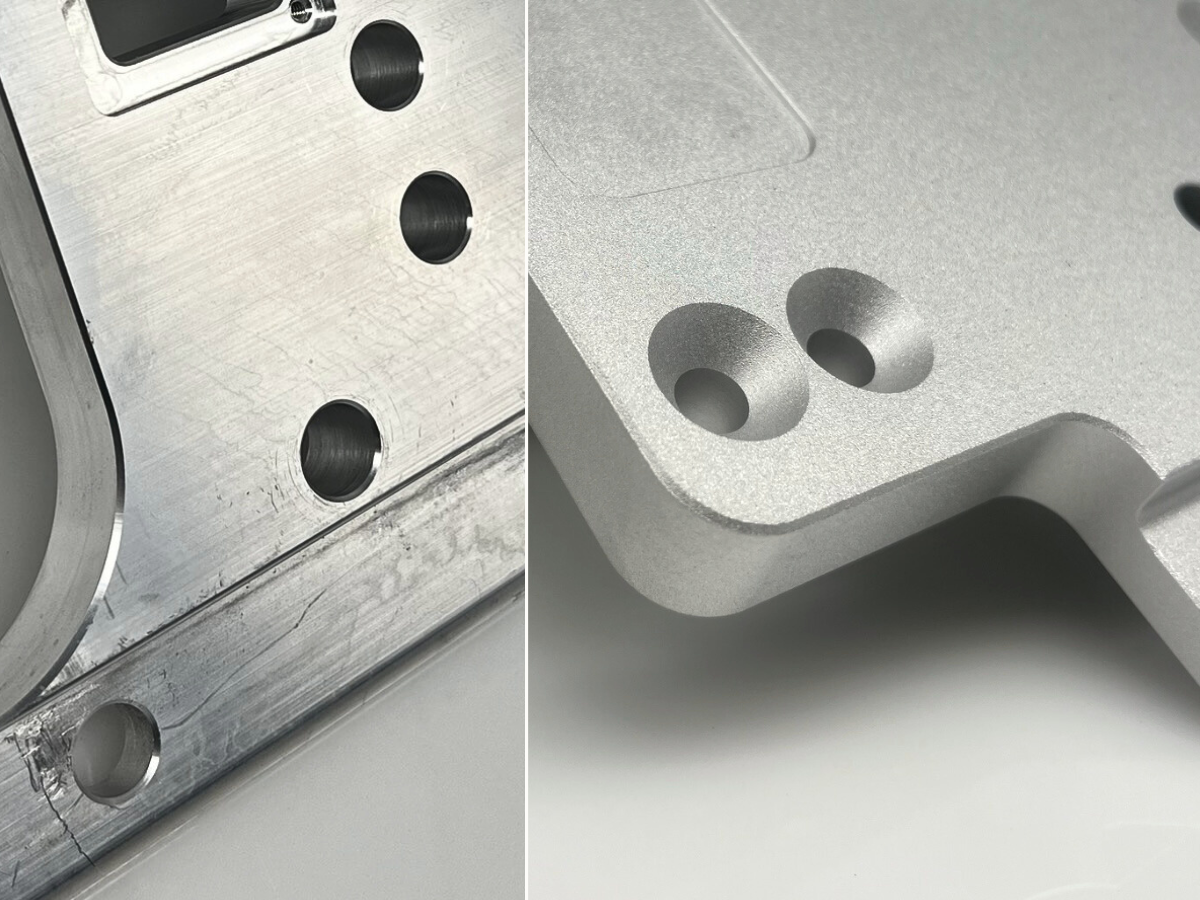

— High Volume; High Quality

WHAT IS DEGREASING?

Vapor Degreasing/Cleaning is a process that uses the vapors of a solvent to clean and remove contaminants like oils, greases, waxes, or dirt from parts and surfaces. The process occurs in a closed system, typically a vapor degreaser, which contains two chambers: one for boiling the solvent and another for condensing its vapors.

-

Vapor degreasing is highly effective for precision cleaning, especially for parts with complex geometries or those requiring high cleanliness standards, such as in aerospace, medical, or electronics industries. It’s fast, leaves no residue, and reduces the risk of damage compared to manual cleaning methods.

High Cleaning Precision: Ideal for intricate or delicate parts with complex geometries.

Residue-Free Finish: Leaves no residue, ensuring spotless surfaces.

Time Efficiency: Cleans and dries parts quickly in one streamlined process.

Environmentally Controlled: Performed in a closed system to reduce solvent emissions and maintain safety.

Consistent Results: Reliable and repeatable cleaning quality.

Material Compatibility: Safe for a wide range of materials, including metals, plastics, and ceramics.

Solvent Reuse: Allows solvent recovery and reuse, lowering operational costs.

Reduced Labor: Minimizes manual handling and cleaning effort.

Compliance with Standards: Meets high industry cleanliness requirements for aerospace, medical, and electronics applications.

Effective for Heavy Contamination: Excels in removing stubborn contaminants like oils, waxes, and greases.

-

The solvent is heated to create vapor.

Parts are suspended in the vapor zone, where the solvent condenses on their cooler surfaces, dissolving and removing contaminants.

The clean solvent drips off, carrying away the impurities, leaving the part thoroughly cleaned.

-

Vapor degreasing/cleaning is commonly used for precision and high-value parts across various industries. Examples include:

Aerospace

Aircraft engine components (e.g., turbines, gears, and bearings).

Structural parts requiring critical cleanliness for performance and safety.

Medical

Surgical instruments and implants (e.g., orthopedic screws, plates, and prosthetics).

Medical device components needing sterilization-ready surfaces.

Electronics

Circuit boards and microelectronics sensitive to residue.

Connectors, switches, and other precision electronic parts.

Automotive

Transmission and engine components.

Fuel injectors, brake system parts, and other high-performance pieces.

Industrial

Precision machinery parts like bearings, gears, and valves.

Tools and molds for manufacturing processes.

Optics

Lenses and mirrors requiring spotless, smudge-free surfaces.

Firearms

Gun barrels, frames, and other parts needing lubricant or coating preparation.

General Manufacturing

Parts with complex geometries, such as tubes, castings, and machined components.

Vapor degreasing is especially effective for parts requiring stringent cleanliness standards, high precision, or preparation for additional processing like coating or bonding.

The EPA has issued a ruling regarding the use of Methylene Chloride after April 28, 2026.

In compliance with this ruling, we will transition our methylene chloride vapor degreasers to N-propyl Bromide before the April 28th, 2026 deadline. This phased approach will allow us to address any challenges that may arise while efficiently managing our existing methylene chloride inventory. For questions or concerns regarding this ruling, reach out to us here.

METHYLENE CHLORIDE;REGULATION UNDER THE TOXIC SUBSTANCES CONTROL ACT (TSCA)